Introduction:

As part of my studies in year 1 of general engineering at TU Dublin, the module of design project entitles us to build a robotic sumo wrestler. This project will be worth a maximum of 50% of the entire module grade and the task is to be completed over a 10 week period with a final week for testing.

This is a vlog website is designed to coenside with the production of my ‘Robosumo’ device and will detail the progress in the construction of the device. The device will be a compact and automated robot, that must seek out and push a opposing robot out a boundary. The device must maintain dimensions within a 10cm by 10cm by 10cm cube. The device must also be fully automatic once initiated.

This project really excited me, I have a keen interest in the small electronic aspect of engineer. Although electrics is a region of which I struggle to grasp and understand, I am excited to get stuck in and learn as I construct and customise our teams robot. The fact of this being a competition also appeals to my competitive side.

WEEK 1

For the first week of the module we received a briefing into the basics of what is expected of us. We were explained what exactly ‘robosumo’ is aswell as how to go about completing it.

This week we were also placed into teams of our choosing, these teams were limited to 3 participants. My team consisted of Alan, Mark and I.

As an introduction to the coding software, each team was assigned a number and challenegd with creating a circuit and flashing the number in binary with and LED. We were assigned number 64 with translates to 1000000 in binary. After an hour or two of trial and error, we final began to understand the coding program and managed to be the 2nd team to complete the task.

WEEK 2

Week 2 was the first week of building the RoboSumo device. But prior to enguaging in the task, we had a brief team meeting to identify all our skills and any possible shortcomings in order maximise efficiency. Alan was identified to be good at coding and was assigned to lead that aspect of the build. Due to Mark’s prior study of Technology in secondary school, he had a well-rounded understanding of circuitry as well as being able to solder very neatly. This allowed me to invest the majority of my attention into the mechanics and design aspect and focus mainly on the chassis and the torque output.

A huge priority for this week was implimenting a single motor using the Arduino board. Much like week 1, the task came with a lot of trial and error in learning how to turn it on and off and changing it’s directions. Eventually we managed to complete this task which was a massive leap forward, once the first motor was coded, the second device could be added with ease.

I spent the majority of our lab session assisting Alan with the coding whilst trying to comprehend it. This prioritisation was done in order to be able to assist at later points and not rely on one individual for all the coding. Outside the labratory class, I began to research designs and aspects of the vehicle in order to gain and edge on other teams. I watched many videos of professional RoboSumo competition as well as investigated: the use of tracks compared to wheels and; the importance of traction and speed. After the research was concluded and the results were discussed with my peers, we agreed to purchase tracks with a support info platform to act as a foundation for the chassis

WEEK 3

The chassis finally arrived and the assembly of it became a top priority. The device came with many small nuts and bolts as well as required specific motors to run effectively. Thankfully we also managed to purchase the motors. These motors were significantly slower than the motors supplies by the college but provided a huge amount of torque at a ratio of 298:1. Due to the up and coming ‘Tip the Can’ competition being a timed competition, we acknowledged the disadvantage we were applying to ourselves but we also recognised the long term advantage in the sumo competition in the final week, and that was agreed to be worth the penalty.

The new motors were soldered to wires and we’re tested in the circuit to ensure it was worming. The main goal of our session in the labratory was to create and apply coding to give us full control of the motors with the acknowledgement of a trigger switch. As part of the time coming competition, our device must seek out and make contact with a can, the swiftly retreat away from the can. This weeks coding was focused on getting the motors to rotate.

Once that task was achieved, the switch was implemented to identify the contact with the can, once the switch is activated, the motors switch and moving in a backwards direction for 3 seconds, this allowed it to safely retreat without leaving the arena.

WEEK 4

This was the final week of work before the ‘Tip the Can’ Challenge, so we must have our robot designed for this challenge by the end of the week. The focus of the week was to ensure the sensors and turning was working correctly and attach it to the motors. The ultrasonic sensor was placed into the breadboard and wired up. The programming was the created to allow the sensor to locate and mark any object within 0.8m. This worked in conjunction with the coding to turn the robot 360° to allow the device to locate the target even if it not in front of it.

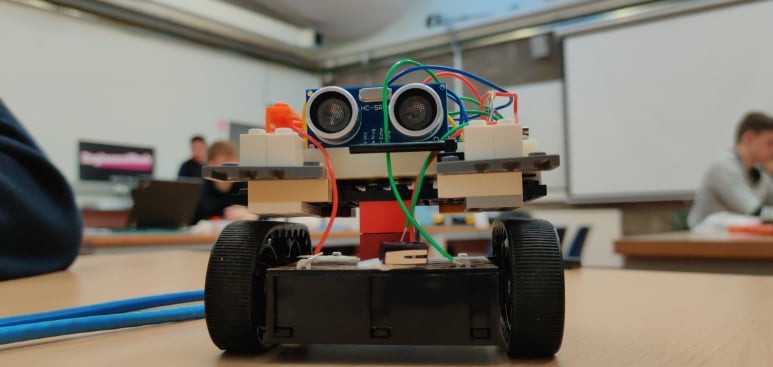

The new chassis, with the new motors installed, it was then adapted to allow the circuit to place on top. This was done by using Lego bricks to elevate the breadboard above the gear treads.

A major accomplishment of this week was completing the code to enable the Ultra-sonic ranger-finder. This coding, created mainly by Alan, allowed our device to spin around, locate the object withing a small radius, and drive directly towards it.A major issue we encountered was the weak point at which the wiring was soldered to the motors. The new motors had very small clips to all ow soldering and it lead to many occasions where the connection would break. For the motors to work, the must be installed and inaccessible with ease, which created a big issue. A support block was attached to the chassis, and using double-sided tape, the wires were stuck to it, removing all strain from the weak point by the inaccessible motors.

Another issue we encountered was the wiring breaking and leaving the exposed copper inside the breadboard. This created issues as the hole was required for the motors and the broken wire was preventing new wire from being placed in it. Eventuality using a sharp blade, the wire was plucked from the board and progress was continued.

WEEK 5

This week was the deadline for the ‘Tip the Can’ challenge, this means out competitor must be assembled for the task and operate without any assistance once activated.

Prior to the lab, in which the challange too place in, our group decided to have a meeting in order to deal with a few minor issues and to enhance the devices working ability. At the meeting, minor bits of code were fixed in order to allow it to work fluidly. Using Lego, pieces of Lego were also attached to the front in order to funnel the can in towards the switch and ensure it gets triggered each time.

The meeting also highlighted the issue of a lack of name. Naming the device is mandatory for this week. We agreed to name it ‘The Hoff’ as marks suggested due to his appreciation for the actor David Haslehoff.

On our first attempts we acheived at time of 14.06 seconds, but due to a minor discrepancy we were disqualified from that attempt. The tracks slightly exceeded the 10cm width. This issue was overcome by pushing the motors back slightly into the chassis, which brought in the tracks, therefore bringing in the width of the device.

On our second attempt, we reached a time of 10.58 seconds. This was acceptable but we were unhappy with the movement of the robot as it had a issue navigating the can due to a angling of the sensors.

On our third and final attempt we received a time of 10.04 seconds. This was the most streamline attempts and it was agreed that a faster time would not be possible.

The completed code of the performing device is as follows:

As mentioned previously, the focus on torque and use of motors to supply torque over speed hindered us in the challenge. Many teams received much faster times of 4-6 seconds. This self-inflicted handicap was acceptable and expected inorder to benefit in the long-term.

Overall I am extremely happy with the performance of out device. It worked at expected and as streamline as possible. Now we start to focus on the next competition, the ‘RoboSumo’ competition.

WEEK 6

Unfortunately this week I was unable to attend the lab class as I had to attend a funeral. This mildly slowed the progress of the week but was not an issue as the next deadline was in a couple weeks.

The main objective for the week was to install a 9 volt battery to the circuit to run independently and operate the motors as tracks. This separate, higher voltage, power supply for the movement of the robot would provide the robot with a higher speed as well as a lengthened duration of the battery life of the batteries, as more batteries are in use.

Outside of the labratory, he began to design and sketch the final design for the competition. This would allowed us to identify how much we need to alter the robot and also what materials would be required to construct it.

With my heading, the design of the robot was drawn up. It would remain similar the robot for the ‘Tip the Can’ but would implement a section of a PVC pipe on the from to act as a ram and attempt to raise the opposing robot’s front wheels off the ground. Sketches were drawn to act as guidelines but it all remains fluid to allow things to change as they proceed wit the construction.

WEEK 7

This week we focus on implementing the infrared sensor. This device will allow out robot to detect it’s proximity to the edge of the arena due to the white paint around the edge. The system allows the light to change course once it detects the lighter colour of the paint.

I soldered wires onto the device, ensure my goggles and the extractor fan was on. Once this was complete the coding commenced. This was a very tedious period of trial and testing in order to figure out the code. After roughly an hour of effort, we realised that bulb in the infrared sensor had blown and the device was unusable. With the aid of a lecturer, a new infrared sensor was implemented and the code was fixed to work fluidly. Once the system detected a change in light, an LED would illuminate. This LED trigger will be elaborated upon next week.

Although this week was not as productive as hoped, overall we are happy that this big milestone is complete. This system was very hard to comprehend and it took the entire lab for us to manifest the working system.

CONCLUSION

Due to the outbreak of the covid-19 virus our time spent in college had to be ceased. This cancellation of college classes resulted in the forced stopping of the module due to differences in student accessibility of facilities to aid in the construction of the robot.

As mentioned previous, our device was very base around the final competition rather than the ‘Tip the can’ competition. This can cause our team to fall down on the over-all rankings as the ‘Tip the can’t competition is now replacing the final one.

This cancellation of the module is very unfortunate as I thoroughly enjoyed participating in it and experiencing new things such as coding. The participation has made me considering enrolling in electrical engineering which would have never been my intention.

Salainis

I had learned already many of the Outland methods of communicating by forest notes rather than trust to the betraying, high-pitched human voice.

None of these was of more use to me than the call for refuge. If any Outlier wished to be private in his place, he raised that call, which all who were within hearing answered.

Then whoever was on his way from that placed hurried, and whoever was coming toward it stayed where he was until he had permission to move on.